Reduced Slurry Agglomeration

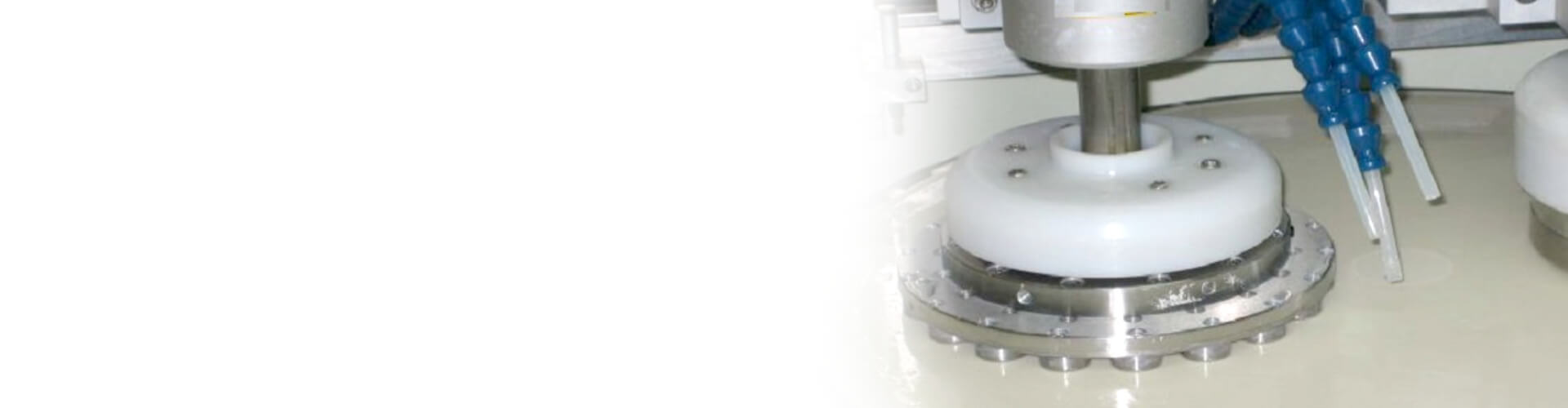

Low shear pump principleThe magnetic levitation technology guarantees that no pump components contact one another, enabling the gentle processing of delicate slurries. The smooth wetted plastic surfaces and the absence of a mechanical bearing, narrow gaps, fissures, and dead-zones ensure the highest standards of slurry health during its lifecycle.

Learn more