减少Slurry聚集

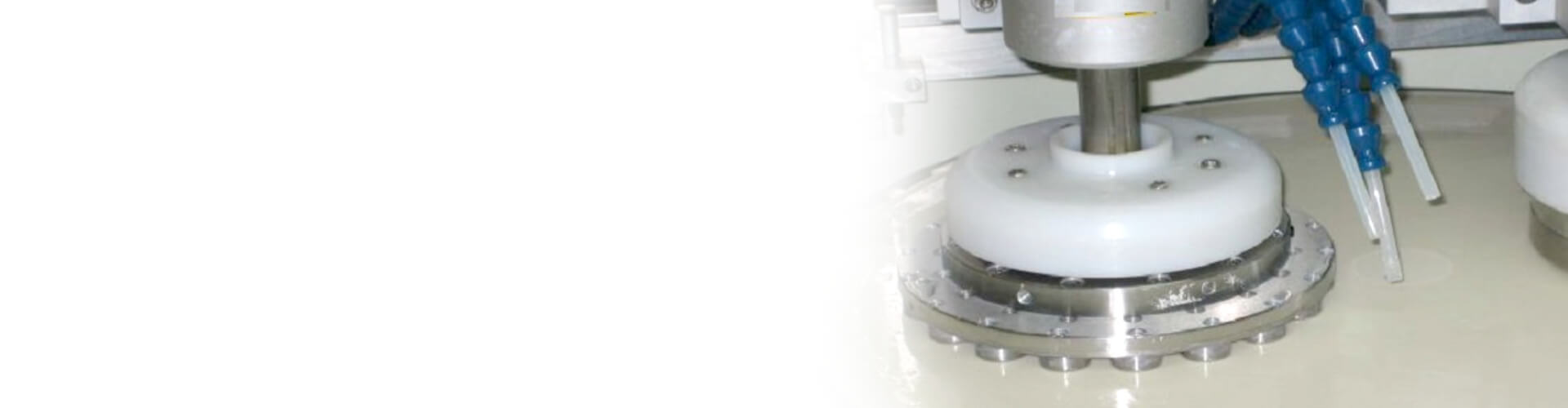

低剪切泵原理磁悬浮技术确保泵组件之间不产生接触,使精细的Slurry能够得到温和处理。光滑的接触液体的塑性材料表面加上无机械轴承、窄缝、裂纹和“死区”,确保了Slurry质量在其生命周期内的最高标准。

Learn more

化学机械抛光(CMP)必须不断改进,以满足下一代集成电路设备制造的严格要求。Slurry的一致性是实现工艺高重复性和均匀性的关键。与Levitronix®泵相比,气动泵可能由于止回阀和其他组件造成剪切应力。泵内的剪切应力会引起Slurry聚集。在CMP中,聚集的Slurry颗粒会导致微小的划痕,从而导致晶圆缺陷。此外,Slurry聚集还会导致过滤器快速堵塞,使维护成本增加。

磁悬浮技术确保泵组件之间不产生接触,使精细的Slurry能够得到温和处理。光滑的接触液体的塑性材料表面加上无机械轴承、窄缝、裂纹和“死区”,确保了Slurry质量在其生命周期内的最高标准。

Learn moreCMP过滤器的寿命与Slurry中大颗粒的浓度直接相关。在波纹管和隔膜泵中,CMP Slurry的大颗粒浓度趋于增加,使用Levitronix®泵可以显着延长过滤器的使用寿命。

Learn moreWe found no results for “keyword”

Please check for typos. The product you are searching for may not be a standard Levitronix product or is not yet on our site.

Can`t find what you are looking for?

Contact usYour account has been created and a verification email

has been sent to your registered email address.

Please check on the verification link included in the email to activate your account.

Return to Sign InAlready have an account?

Please enter your information below.

Not a member? Create account