100-90649

PuraLev® Driver System PLD-200SU.3

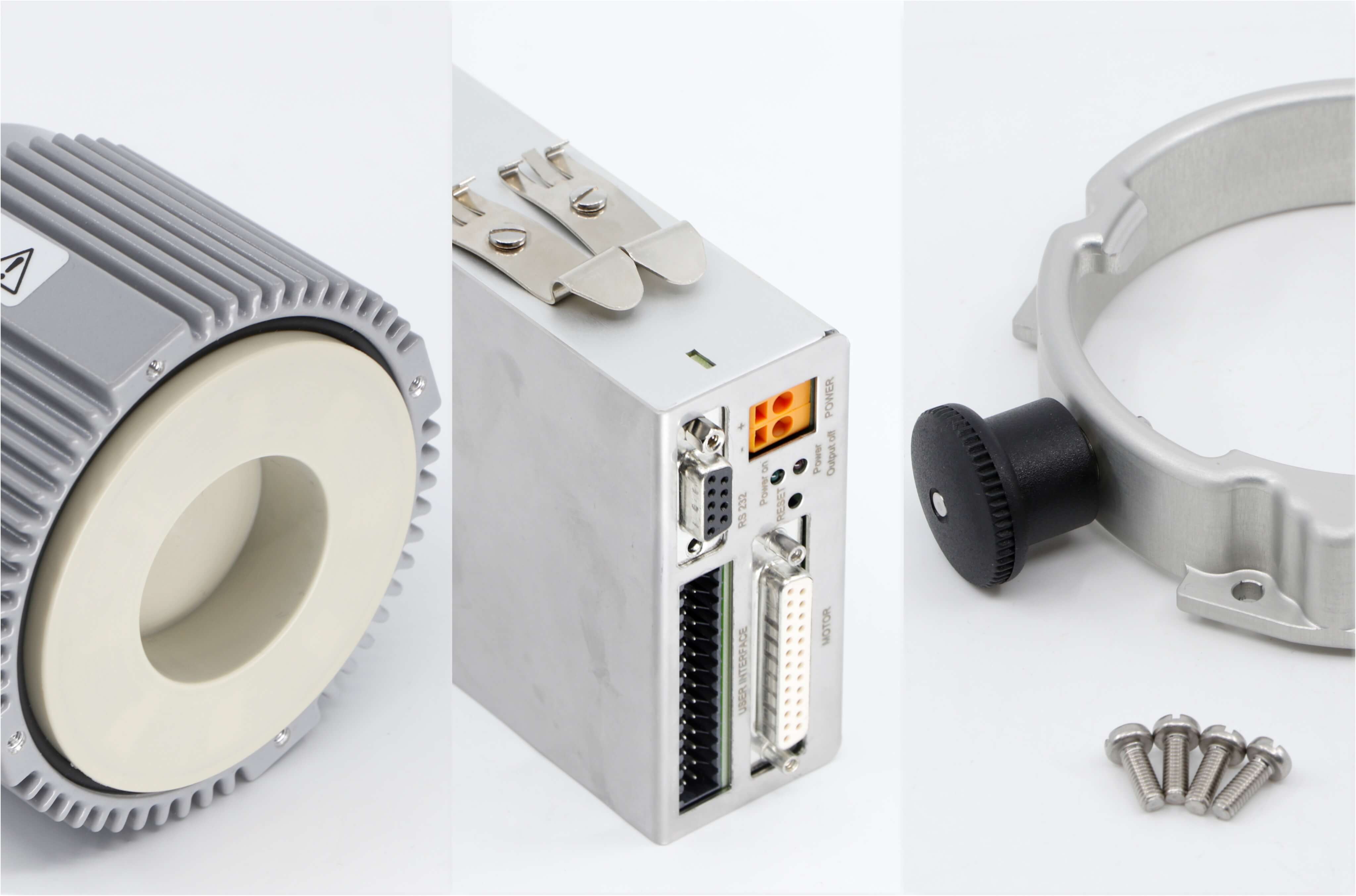

Consists of:

Availability on request

Max. Flow (l/min)

21

Max. diff. Pressure (bar)

2

Max. Viscosity

20 cP

Max. Liquid Temperature

60°C / 140°F

Service/Control Interface

RS232 and PLC Interface

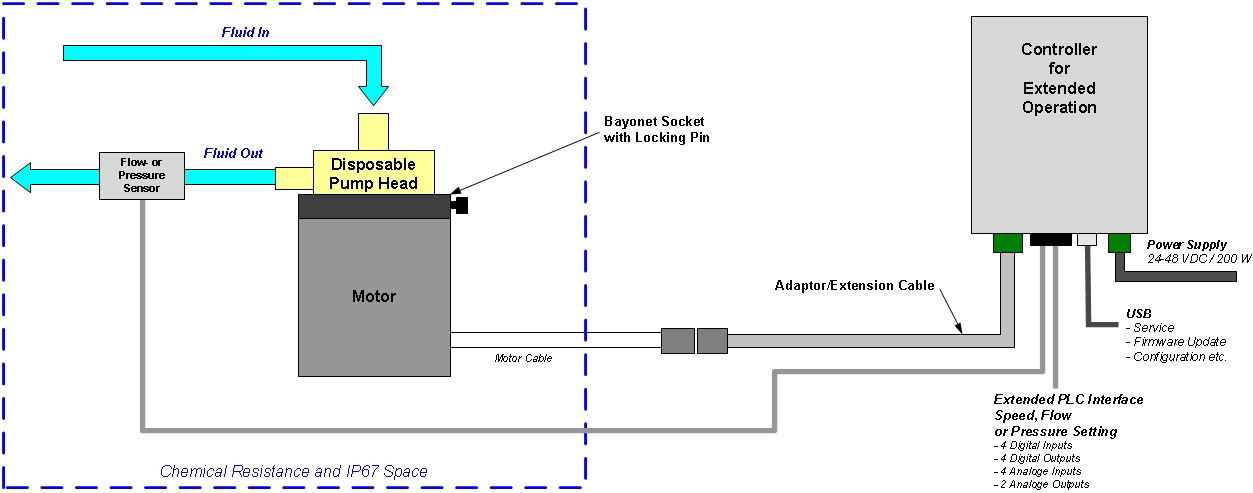

PuraLev® Single-Use pump systems are designed for demanding fluid applications in bioprocessing where extremely low shear, pulsation-free, and continuously controlled flow ensure the highest product yield. Based on the principle of magnetic levitation, the pump impeller is suspended, contact-free, inside a sealed casing and is driven by the magnetic field of the motor resulting in a continuous smooth flow.

Specifications

| Max. Flow (l/min) | 21 |

|---|---|

| Max. diff. Pressure (bar) | 2 |

| Max. Viscosity | 20 cP |

| Mounting Type | Bayonet type with locking pin |

| Sterilization Methods | Gamma radiation up to 40 kGy |

| Fitting Size | 1/2” |

| Fitting Type | Triclamp |

| Pump Head Material | Polypropylene |

| Impeller Material | Polypropylene |

| Sealing Ring | Infrared welding |

| Screws | 4 pcs M3 x 8mm (Stainless Steel) |

| Wet Volume (without drain port) | 24 ml |

| Max. Liquid Temperature | 60°C / 140°F |

| Motor/Driver Coating | ETFE |

| Direct Connection to Controller | Yes |

| Connector Type | 1x D-SUB |

| Cable Lenght (mm) | 5 000 |

| Cable Jacket | FEP |

| Ex Protection | Other |

| Power | 200 W |

| Voltage | 24 VDC |

| PLC Interface | up to 2 analog outputs 0-5 V up to 4 analog inputs 2 with 4-20 mA, 2 with 0-10 V up to 4 digital inputs 0-24 V (optocoupler) up to 4 digital outputs 0-24 V (relays) |

| Service/Control Interface | RS232 and PLC Interface |

| Housing/Material | Polypropylene |

Downloads

System Configuration